MotorGuard™ 15 — DC Motor Spike Suppressor (15A Module)

MotorGuard™ 15 — DC Motor Spike Suppressor (15A Module)

Clean motor shutdown. No spikes. No surprises.

Every time you switch off a DC motor — boost pump, flap motor, trim, canopy actuator, or smoke pump — it sends a voltage spike back toward your switches, breakers, radios, and EFIS.

MotorGuard™ 15 stops that spike at the source.

Here’s what changes for you:

No more electrical pops or clicks in the headset or radios.

No nuisance breaker trips when a motor stops abruptly.

No back-fed spikes hitting your panel switches or avionics bus.

Your cockpit stays stable and predictable — even with multiple motors cycling.

Installation takes two ring terminals. Mount the MotorGuard™ directly at the motor, and it redundantly absorbs the shutdown spike before it ever reaches the cockpit wiring.

Whether it's a 15-amp boost pump or a small trim motor, you get clean shutdowns, reduced EMI, and a calmer electrical system — automatically.

A simple, ready-to-install module built for experimental aircraft.

Protection you can feel on every flight.

MotorGuard™ 15

Aviation-Grade Protection for DC Motor Loads in Experimental Aircraft

Made by a pilot for pilots, the MotorGuard™ 15 is a compact, purpose-built protection module for 12–14 VDC motor-driven accessories in RVs, F-1s, and other experimental aircraft. Each unit is manufactured and assembled in Marion, Iowa, functionally tested after your order is placed, and built to survive vibration, heat, and real aviation environments.

Originally created for smoke-system motors, the MotorGuard™ 15 is suitable for any small DC motor on the aircraft — flap motors, trim motors, cooling fans, boost pumps, actuators, and more.

Why It Matters

When a DC motor is switched OFF, its magnetic field collapses and produces a brief voltage spike. If not controlled at the source, that spike travels backward through the electrical bus that powers that motor, affecting any equipment sharing that same bus path.

The MotorGuard™ 15 captures that shutdown spike directly at the motor terminals, preventing it from ever entering the upstream bus.

Internal Protection System

Inside the enclosure is a sealed, dual-path suppression network engineered for inductive DC motor loads. When the motor turns OFF, the network instantly absorbs and redirects the collapse energy locally.

No spike enters the motor’s electrical bus

No arcing in panel switches that feed the motor

No nuisance breaker trips on that circuit

No noise injection into radios or EFIS sharing the same bus

All components are mounted on a dedicated internal fixture, strain-relieved, and enclosed in a rigid housing. No service is required — installation is simply attaching two ring-terminated leads to the motor posts.

Features

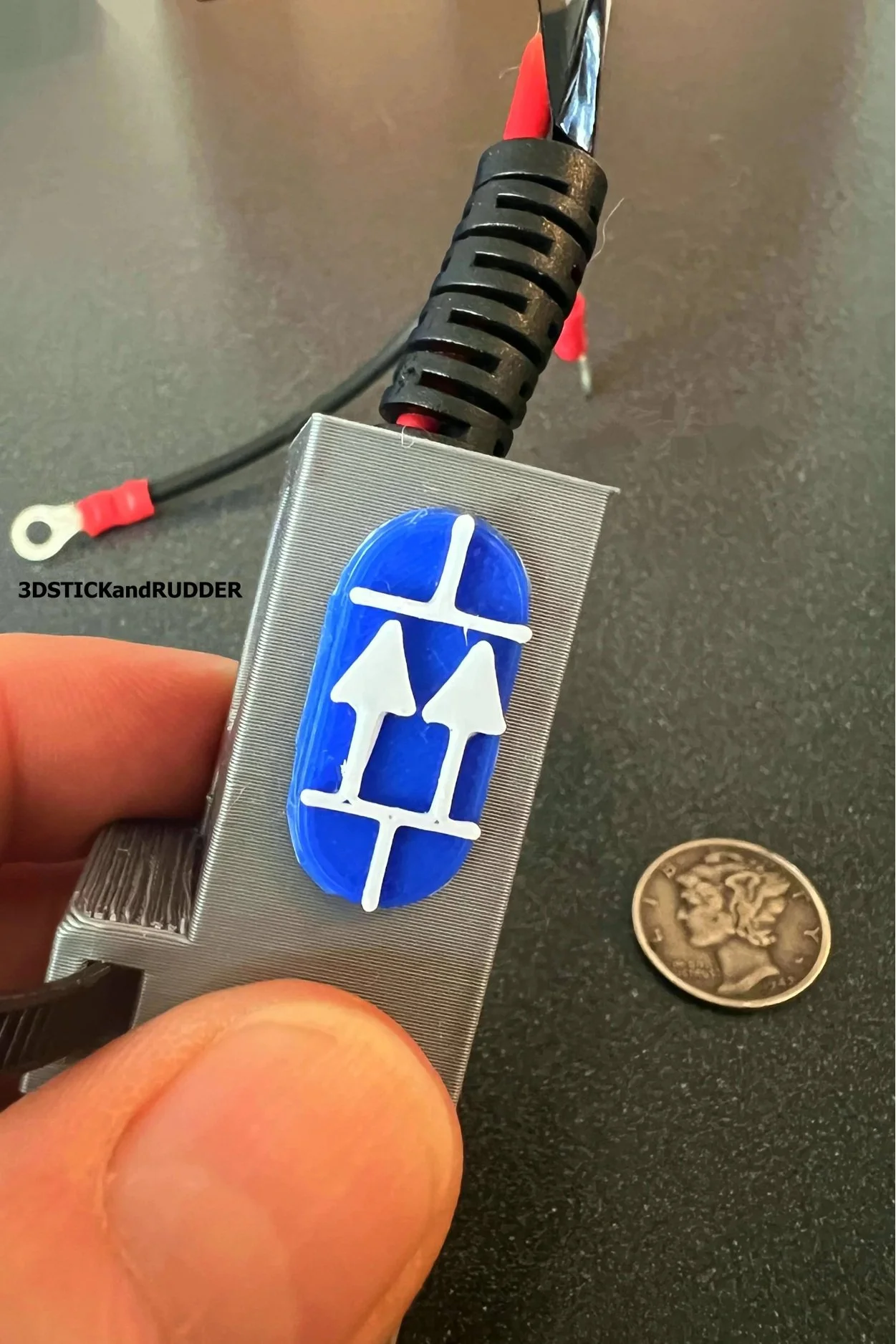

Enclosure

Printed in durable silver or black 3D thermoplastic

Extended rectangular body with six weight-reduction hog-outs

Weight: 1 1/8 oz.

Size: 56mm (L) x 18mm (H) x 10mm (T)

Internal fixture secures the protection network

Integrated strain-relief bobbin with 18 AWG leads

Impact-resistant, temperature-stable, vibration-ready

Manufactured, assembled, functionally tested and packaged in the USA

Electrical Protection

Designed for 12–14 VDC aircraft systems

Supports motor loads up to 15A running current

Systems Protected (Indirectly)

The module does not connect to these systems — it protects them by preventing the motor’s shutdown spike from entering the bus they share with the motor:

Panel-mounted switches and rockers on the same feed

Circuit breakers and fuses on that circuit

Avionics bus components (EFIS / EMS / GPS / ADS-B) if sharing the same bus

Radios and intercom audio systems on that bus

Voltage regulator and alternator field circuits with shared bus paths

Auxiliary/boost fuel pump motors

Flap, trim, and actuator motors

Contactor coils

Cooling fans

Any device on the same electrical bus benefits when shutdown noise is stopped at the motor instead of being allowed to travel upstream.

Wiring & Installation

Red lead (shorter): motor positive terminal

Black lead (longer): motor negative terminal

18 AWG leads with insulated ring terminals

Polarity schematic printed on the enclosure

Mounts directly at the motor

Installation schematic included

What the MotorGuard™ 15 Does for Your Aircraft

Redundantly eliminates motor-shutdown voltage spikes at the source

Prevents arcing and contact erosion in cockpit switches feeding that motor

Reduces nuisance breaker trips on that circuit

Prevents shutdown noise from entering the shared bus

Helps maintain stable avionics operation when motors turn OFF

Reduces stress on the alternator field and voltage regulator (shared-bus scenarios)

Provides a clean, enclosed, professional solution

Condition

Mint, ready to install

Built and functionally tested after order

Non-smoker manufacturing facility

Photos may depict example installations. Sale includes the MotorGuard™ 15 module and leads only.